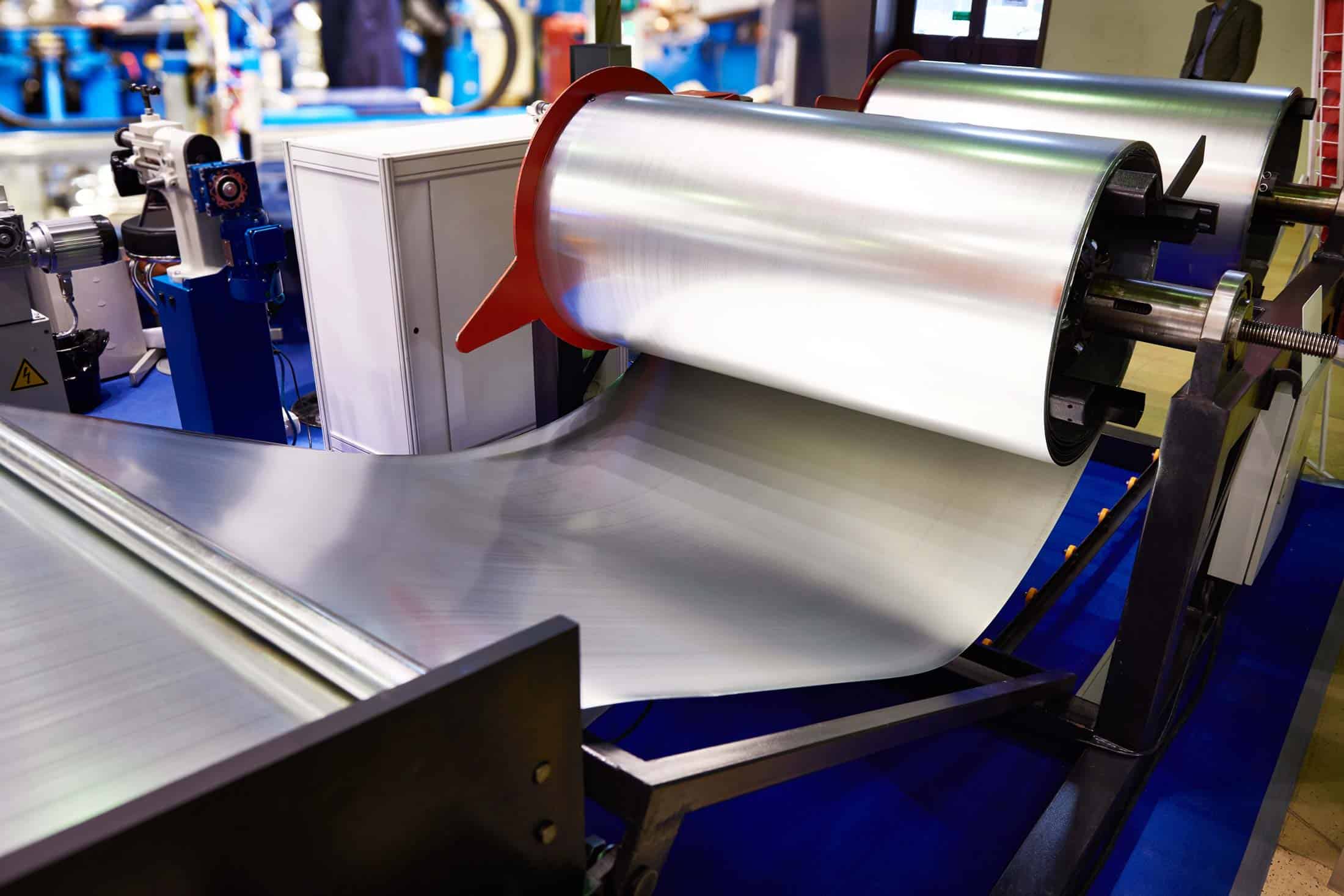

In rolling mills, an efficient and accurate setup is vital for meeting quality and production requirements for strip processing.

Essco scraper blades and systems are a proven roll-cleaning technology for steel and aluminum cold and hot rolling mills. They help maintain surface quality and ensure tolerances are met, as well as enhance overall productivity and maximize yield.

Steel and aluminum strip contacts multiple rollers throughout processing, which can involve wet and dry conditions. It’s a harsh environment. Every Essco scraper system is custom-built to the precise specifications of each application. Its process knowledge and commitment to meeting application requirements has earned Essco the trust of customers across the globe.

Essco scraper blades and systems remove strip scale and oxide build-up, and keep lubricating fluid from marking the strip. They also remove particles from rollers engineered for specific applications, such as coil coating, hot dip galvanizing, electro-galvanizing, pickling and other metal manufacturing processes. Effective roll cleaning from Essco prevents damage to the roller surfaces, saving resources and helping optimize rolling results that make strip processing lines more competitive.

Essco has earned its reputation as the quality leader in scraper systems by consistently providing customers with innovative and high-quality products that are supported with superior service and value.

Sign up for industry alerts, our latest news, thoughts and insights from Essco.

All Rights Reserved.

Fill out the form below.

"*" indicates required fields