Essco offers a wide variety of standard and custom blade holders, with a model suitable for any application. Designed to meet specific needs, the holders are manufactured from 316L stainless steel, which provides high corrosion resistance. The heavy-duty construction ensures consistent performance in the most demanding environments.

Whether your setup calls for the rigid styling and versatility of a KF holder, the even blade pressure of the ETUniform™, or a unique specialty design, Essco will deliver precisely the blade and holder configuration for a job well done.

Commitment to application performance drives every step in the development process, from engineering to manufacturing to installation. For example, machining of the blade holder-mounting surface is critical, which is why Essco takes great care to ensure the surface treatment will conform as needed, whether straight or crowned. Essco goes even further to chart the machining results in thousandths of an inch, and then maintains the chart as a permanent quality control record of the blade.

Essco blade holders are also easy to adjust and maintain. This makes them the ideal choice for high-stress situations, such as pulp and paper applications, for which there are multiple holder options.

Essco rigid blade holders can be precisely profiled to the material roll with micro-adjusting screws for optimum performance.

Conforming blade holders provide uniform blade-to-roll contact pressure that results in efficient, higher-quality doctoring.

Essco supplies creping blades and creping doctors to nearly every North American tissue maker. Our heavy-duty creping blade holders provide excellent performance with minimal setup and maintenance.

Filter Results

| Holder | Type | Summary | Description |

|---|---|---|---|

Accu-Crepe  | Creping | Construction: 316 stainless steel

Use: Creping applications

| The Essco Accu-Crepe blade holder is a proprietary creping doctor design with cross-machine and fluid-dampened profiling capabilities. The holder provides profiling accuracy that ensures uniform creping characteristics across the roll, improved blade life, and reduces Yankee dryer wear, all of which deliver superior ROI.

|

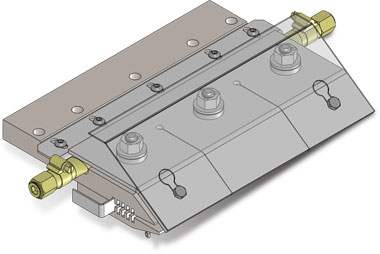

AquaClean™  | Rigid | Construction: 316L stainless steel

Use: Coater wash backup roll

| The Essco AquaClean™ doctor system is a proprietary design specifically for use on coater wash backup rolls. AquaClean™ blade holders are fully sealed for improved run capabilities and product quality. They also feature a special air load tube and full-length seal rings that provide effective and leak-free cleaning, which reduces roll maintenance.

|

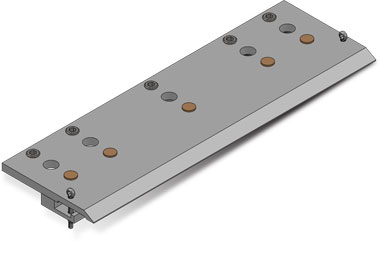

ETU Finger Type  | Conforming | Construction: 316 stainless steel

Use: Paper machine wet end, press, ad dry end; industrial roll cleaning and flaking.

| The ETU Finger Type blade holder features Essco's original tube-loaded design with blade support fingers spanning the load and unload tube. The holder combines higher load capabilities with slightly reduced conforming ability. The ETU Finger Type blade holder is recommended only for replacement applications where a newer design cannot be easily accommodated.

|

ETU ST  | Conforming | Construction: 316 stainless steel

Use: Paper machine wet end and dry end.

| The ETU-ST blade holder features a lighter-duty design with a formed tube tray and single top plate. The holder offers a lower-cost conforming option for less-demanding applications.

|

ETU-OraCrepe™  | Creping | Construction: 316 stainless steel

Use: Yankee creping and cleaning doctors.

| The ETU-OraCrepe is a heavy-duty, self-conforming blade holder with pneumatic-tube loading. The holder provides excellent performance and durability for high-load Yankee creping and cleaning applications. The Essco ETU-OraCrepe blade holder features:

|

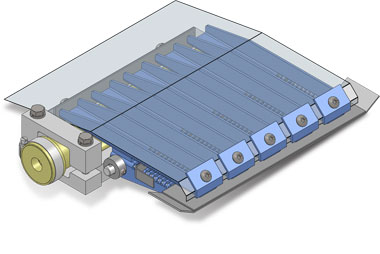

ETUniform™  | Conforming | Construction: 316 stainless steel

Use: Fourdrinier rolls; press rolls; dryers & sweat dryers; MG yankees; calenders & reel drums

| The ETUniform™ conforming blade holder provides even blade-to-roll pressure across the full length of the machine. Durable stainless-steel construction makes the holder perfect for tough operating conditions of critical doctor positions. The ETUniform™ allows for:

|

FlexForm™  | Conforming | Construction: 316 stainless steel

Use: Paper machine wet end and dry end; industrial roll cleaning and flaking.

| The FlexForm blade holder offers similar performance to the ETUniform™ holder, but at a lower cost and less maintenance. The holder conforms to the roll profile without the need for micro-adjusting screws, and the segmented fingers reduce fiber buildup.

|

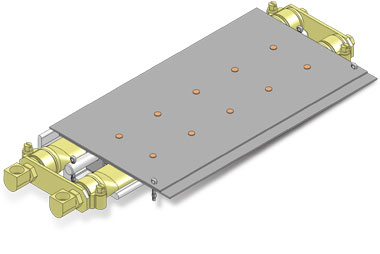

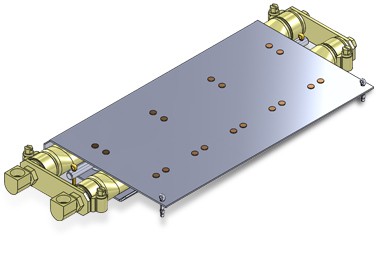

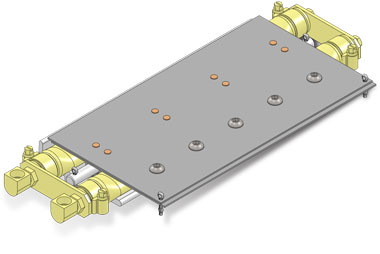

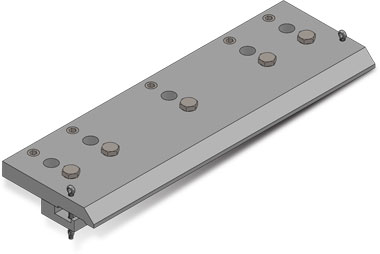

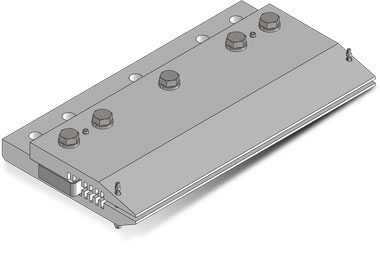

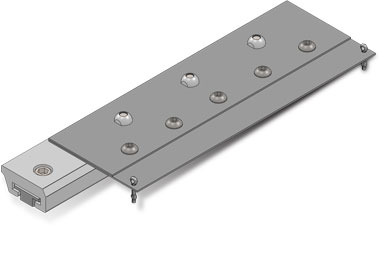

FlexForm™ ETU-ER  | Conforming | Construction: 316 stainless steel

Use: Paper machine wet end and dry end; industrial roll cleaning and flaking.

| The Flexform™ ETU-ER blade holder mounted on a T-bar. This option makes it easy to slide the complete blade holder out of the machine for cleaning and maintenance. Additional design features of the Flexform ETU-ER include:

|

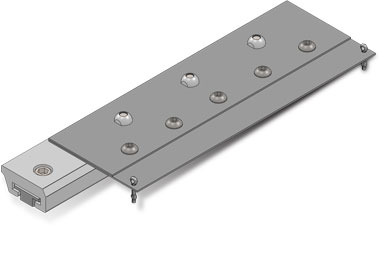

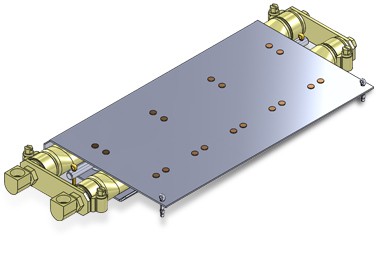

KF-35A  | Rigid | Construction: 316 stainless steel

Use: Fourdrinier, press, dryer, calender, reel, and off-machine applications. Can be customized for special purposes.

| The rugged and versatile Essco KF-35A is the industry standard for rigid blade holders. It is suitable for most doctor positions and accepts almost any blade thickness. Micro-adjusting screws allow a precise blade-to-roll fit as roll conditions change. And the design of the KF-35A rigid doctor blade holder allows for end or front removal of the blade, which minimizes downtime.

|

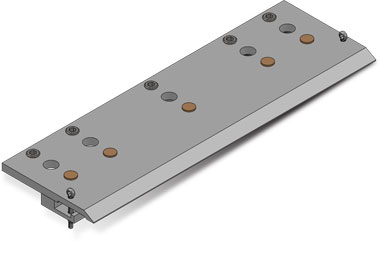

KF-45A  | Rigid | Construction: 316 stainless steel

Use: Yankee cut-off, double drum dryer, and flaker position.

| The KF-45A is a heavy-duty blade holder designed for high-loading applications such as Yankee cut-off doctors, double drum or flaking positions, and other industrial processes. The holder is rugged and economical, with micro-adjusting screws for precise alignment.

|

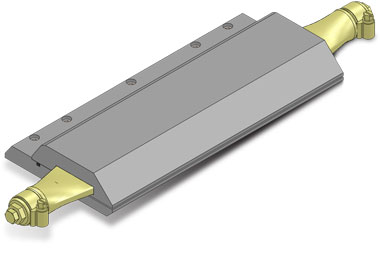

Ladder-Type  | Creping | Construction: 316 stainless steel

Use: Yankee creping, cleaning, and cut-off doctors.

| The Essco Ladder-Type blade holder features heavy-duty stainless steel construction that offers a dependable, rigid-style design for Yankee creping operations. The holder incorporates ladder slots and an adjustable lifting strip to allow for various blade widths as blades are reground.

|

Filter Results

The Flexform™ ETU-ER blade holder mounted on a T-bar. This option makes it easy to slide the complete blade holder out of the machine for cleaning and maintenance.

Additional design features of the Flexform ETU-ER include:

Fill out the form below.

"*" indicates required fields